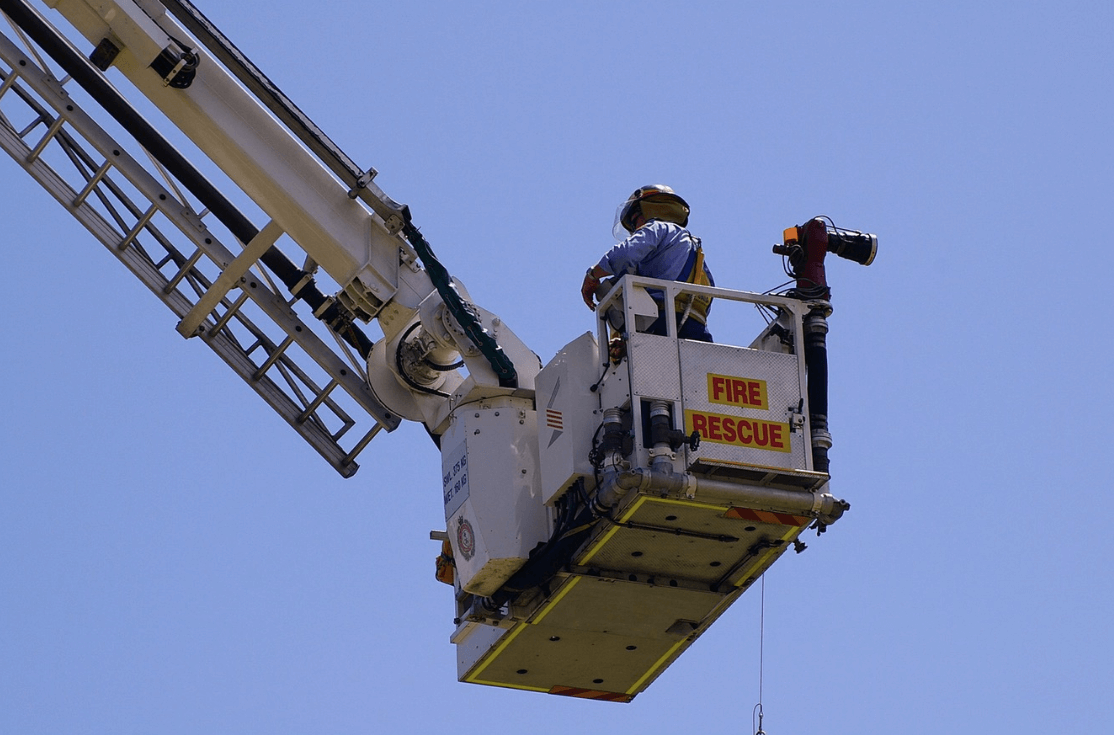

Initially, it was used by workers to reach inaccessible places like trimming high tree branches, fruit picking, and power lines.

Today, these machines are used to clean windows, clear guttering, fix roofs, repair fascia, and are the best substitute to scaffolding- offering an easy way to access hard-to-reach areas at great heights. With so much popularity and convenience, the machines have entered into the maintenance work, and media world for aerial photography in events.

These are also popular to be called as a man lift, boom lift, hydra ladder, or basket crane. Specialized forklifts and order pickers sometimes called cherry pickers too, that are used in warehouses for selecting items from pallet racking at great heights.

While some cherry pickers come with automatic safety controls, some have the outstanding telescopic potentiality to adjust the reach. Since there are various types of cherry pickers available, it is important to choose the right type according to your specific business needs. We have covered everything you should ask yourself while choosing the right cherry picker so that you can carry out work safely:

Are You Going To Work Indoors Or Outdoors?

Indoors

While working indoors using such heavy machines, the major issue comes is the ventilation, especially when the equipment is diesel-powered, since it will emit harmful fumes.

Thus, choosing an electric machine will perhaps be preferable over a fuel one. However, check the inside measurements of the narrowest space- the equipment will have to fit in. You should also check the turning radius for comfortable handling and use in any space you want to turn the machine in.

Outdoors

Working outdoors means working at different ground conditions, which often includes rough terrain surfaces. Considering the ground surface and checking the gradient that the machine is capable of will help make an informed decision according to its specifications.

If anything has to do with groundwater, you need a cherry picker that has outriggers to spread the load evenly and prevent accidents. However, whether you work inside or outside, all operators are mandated to complete the training and gain cherry picker certification to operate the machine with utmost safety.

How Much Weight Can The Bucket Handle?

It is important to consider the total weight that is going to be put in the bucket. The weight in the bucket defines the height that you can reach. The minimal the buckets weigh, the higher the chances of a cherry picker to be able to reach easily and safely. Remember that the weight of the bucket includes both the weight of your tools and the weight of the person. You can compare this in different cherry pickers models available.

How High Can It Reach?

This is one of the most critical factors as you need a cherry picker to reach elevated heights. Right?

This includes the vertical height up from the ground as well as the horizontal stretch you want to achieve while you are at height. Keep in mind that cherry pickers are measured from the ground, and include the height of a person (so you don’t have to add your own height into the measurements given in the specifications).

Similarly, horizontal reach includes the length of the outstretched arm. Considering all factors like weight and reach will help you make the right decision.

Is Cherry Picker Training Mandatory?

While they are an incredibly versatile and useful piece of equipment, poor handling and incomplete knowledge can pose some severe injuries to the workers. Even the order pickers contribute to workplace injuries, and most of them are due to operator error.

It is necessary for workers to get comprehensive training so that they can safely operate the equipment both indoors and outdoors!